CASE STUDY

Aviation Additive Upgrade - Viva Energy Fuel Terminal

Key Information

-

CLIENT

Viva Energy Australia

-

PROJECT

Viva Energy Pinkenba, Brisbane

-

PROJECT DETAILS

F34 Aviation Additive System Upgrade

-

FUEL TANK BUILD & COMMISIONING

Nqpetro Pty Ltd.

-

DURATION

12 weeks

-

INDUSTRY

Aviation

Project overview

Grande & Bloc tanks being put to the ultimate test with this F34 system upgrade (Nalco & FSII [methyl carbitol]) including upgrade of aviation bays to an automated Accuload 4 system.

Whilst not storing aviation fuel directly, they were part of the upgrade to the terminal’s aviation additive system so were required to have an aviation-grade specification.

What’s the difference with an aviation tank? It’s what you can’t see…

The number one priority for aviation fuel storage is avoiding contamination. Our aviation tanks have an inner primary tank made of 100% stainless steel. All associated pipework and fittings are also made of stainless steel.

Sloping floors to the inner tank ensure a free drainage floor pan and allow for the safe removal of water condensation as part of a daily maintenance program.

These features not only meet all safety requirements and add to the longevity of the tank, they also give you complete peace of mind with the operational integrity of the tank overall.

Fuel Focus

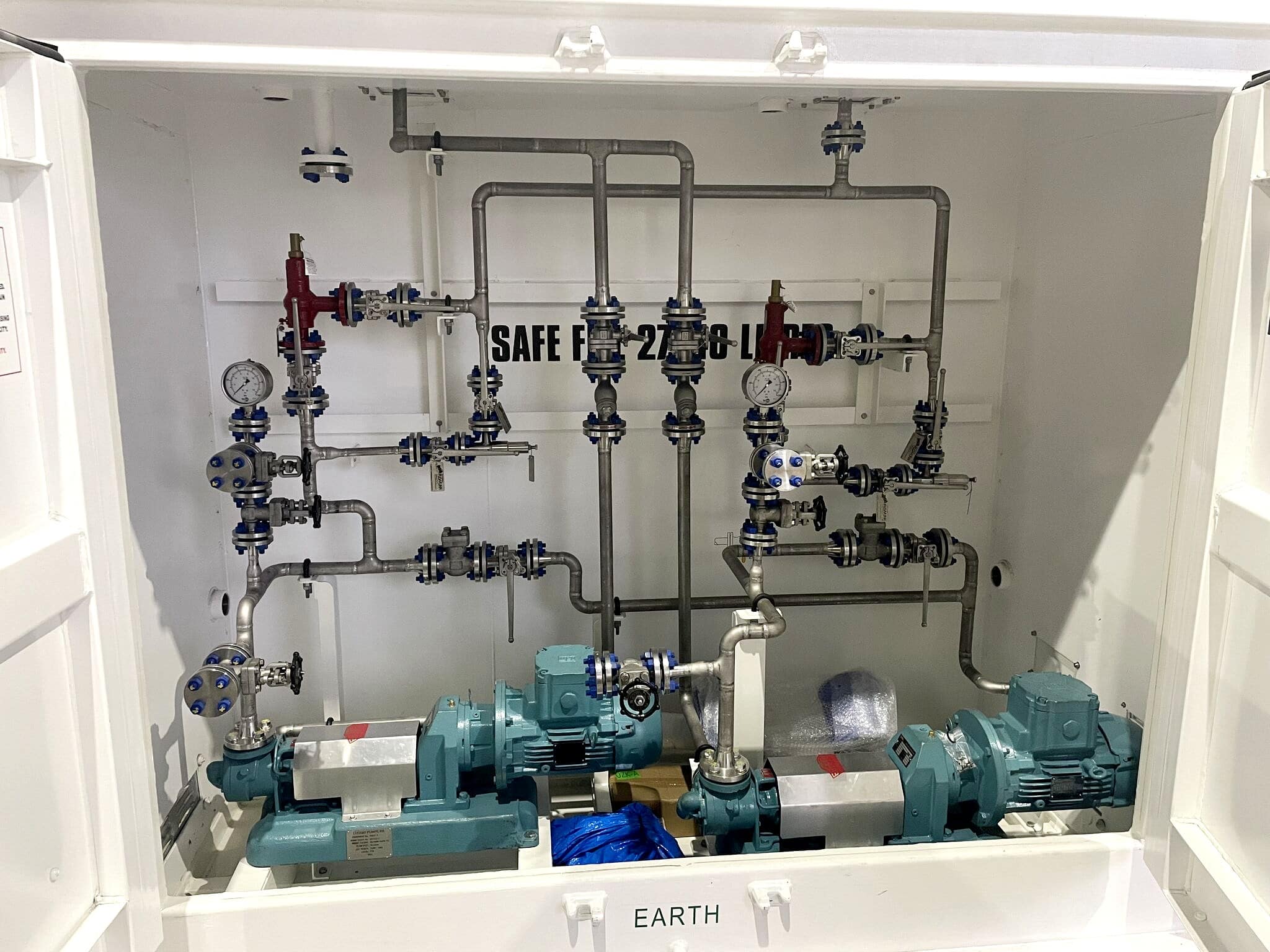

- Installation of new aviation tanks, pipelines, filter water separators, additive injection systems, metering runs and loading arms.

- Grande 30 Aviation tank: SFL - 27,740L storing and pumping Methyl Carbitol (fuel system icing inhibitor - FSII) to terminal gantry loading arms for F34.

- Bloc 1000 Aviation tank: SFL - 1,000L storinig and pumping Nalco (corrosion inhibitor) to terminal gantry loading arms for F34.

- Stainless steel small bore pipework designed and finished with Class 2 welding inside pump bay on Grande 30 and on manufactured skid for Bloc 1000.

Featured Product