Remote control – getting fuel storage right in remote locations

When you’re a regional council or a transport business operating in a remote location, fuel usage is a significant cost.

Our experience working with remote operations means we know where your pain points are, and we can help you design solutions that are right for you.

Broadly, some of the most common problems our remote customers face relate to fuel theft and inefficient refuelling logistics.

Think creatively – explore the latest fuel storage options

Losing fuel by theft from your tank or your vehicle is a common problem.

Many operators try to run fuel levels down at the end of every day to minimise the attraction for would-be thieves, but fuel storage has come a long way and the range of fuel theft solutions available is as extensive as the different needs of remote operations.

If you want to make a positive change that will help contain fuel costs and boost your bottom line, a good starting point is your fuel storage tanks. It may seem obvious, but this is an area where upgrading to newer solutions can have a huge impact.

For example, we’ve worked over the last several years with a local council covering a region of 94,000 hectares in outback Australia. When they first came to us, their fuel storage systems consisted of old-style, single skinned tanks in frames mounted to semi-trailers. While the trailers could transport the tanks to their various work locations, they were then there for the duration of the job – often several months. What’s more, the tanks weren’t secure and could easily be drained by thieves.

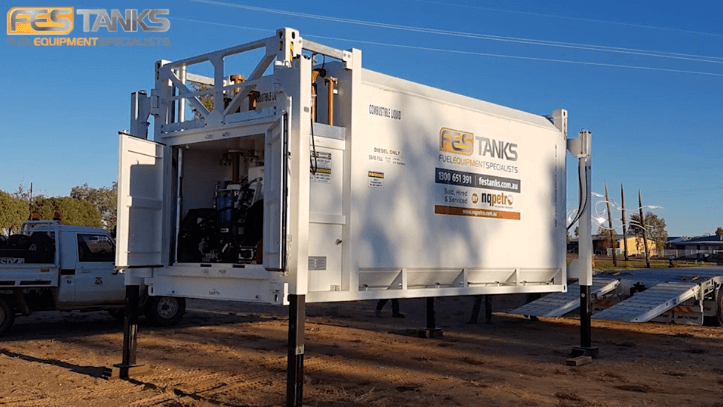

Upgrading to our aboveground fuel storage tanks that are self bunded and fully transportable meant not only was the fuel far more secure in dual-walled environment with lockable access hatches, but the tanks could easily be transported between work sites and left on-site while the truck and trailer went back into the fleet, maximising use of their equipment.

What’s more, moving from old-style cylindrical tanks at their depots meant they could significantly increase their storage capacity without increasing their storage footprint.

Finally, fuel theft was reduced because, after all, it’s a lot harder to break into a fuel tank that’s double-skinned and has lockable access doors. Using a modern, integrated fuel management system that can monitor usage to the litre also makes it easy to identify and address problems early.

Act logically – getting the logistics right

Once you’ve considered the tanks you’re using, the next step is to look at the location of your storage and your fuel management systems.

If your vehicles have to travel long distances to refuel, that’s an inefficient use of time, fuel and plant resources.

There’s a human resources element too – when you’re covering large distances and have fuel stored at one or two sites, sending somebody out to read fuel levels and monitor usage can be a significant task.

Talking to an expert about the best solution to suit your workflow can help you find new ways to maximise efficiency and minimise waste.

Using a combination of fixed fuel storage at depots or bases, with mobile tanks that can be dropped at remote work sites and moved to meet work requirements, is often a good choice. And with the introduction of modern level gauging systems that can monitor fuel levels remotely, it’s now easier than ever to monitor fuel levels and usage at all your storage locations without the expense of manual checks on site.

Ask us about a solution for your business

Whatever your business, if you’re working in a remote environment there’ll be challenges.

With more than 100 years combined experience in the fuel industry, our technicians are experts in remote refuelling solutions and can work with you to plan the best solutions for your operation.

Call us on 1300-651-391 or get in touch here.